::: Vertical Deepwell Turbine Pump

Ideal for Agriculture, Municipal Water Works, Lift Irrigation Scheme, Industrial & Fire Fighting

Services.

Applications >> Applications >>

- Irrigation in Agriculture and Horticulture from Deep

Tubewell, Openwell, Canal and River Water

- Lift Irrigation

- Municipal Water Supply

- Rural and Urban Water Supply

- Domestic, Public Utility & Industrial Water Supply in High Rise Building, Residence Colony and Overhead Tank

- Sea Water, Raw and Storm Water Services

- Fire Fighting Services

- Mines and Dam Dewatering

- Special Application for Handling Oil, Petroleum and Treated Liquids.

Different Types of Driving Arrangement >>

|

|

|

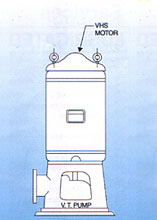

Vertical Hollow Shaft

Motor Drive |

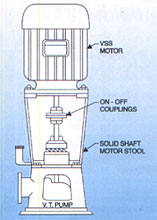

Vertical Solid Shaft

Motor Drive |

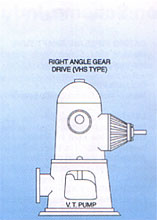

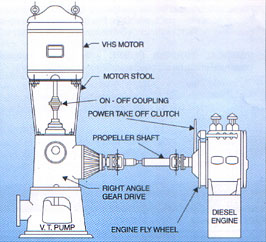

V H S Gear Drive Through

Diesel Engine |

| |

|

|

|

|

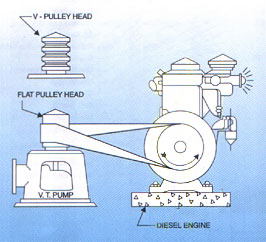

V or Flat belt pulley head drive

through diesel engine |

Combination Gear drive through

VHS motor and diesel engine |

Oil Lubricated / Water Lubricated Vertical Deepwell Turbine Pump

|

Oil Lubricated |

Water Lubricated |

|

|

|

| |

-- Capacity

Ranging from 100 to over 12,000 LPM capacity from deep tubewell of 150 mm to 500 mm diameter and up to 92 meters depth. Driven either by oil engine, or electric motor Conforming to IS:1710.

-- Bowl

Made of close-grained cast iron. Houses bronze bowl bearing, S.S. impeller shaft & impeller. Has hydraulically profiled guide vanes for higher efficiency.

-- Impeller

Made of close-grained cast iron or bronze. Single suction, enclosed or semi-enclosed type. Dynamically balanced. Clamped by draw-out type collet and locknut to stainless steel shaft.

-- Discharge Case

Made of close-grained cast iron. Houses bronze bearing. Guided water flow into column assembly. The discharge case in oil lubricated turbine pumps has intermediate bearing, lantern ring, asbestos-plated yarn seal (gland packing) and discharge case bearing for line shaft tube. Prevents water from entering the line shaft tube as the high pressure water is bypassed through relief ports in the lantern ring.

The discharge case in water lubricated turbine pumps has a sand collar which prevents entry of sand into the discharge case bearing.

|

-- Lubrication

For oil lubricated turbine pumps, manual lubricator or automatic electric oil lubricator available. Separate pre lubricating tank is available for water lubricated turbine pump.

-- Suction Case

Made of closed-grained cast iron. Houses bronze bearing and sand collar which prevents entry of sand into suction case

bearing. Guides flow of water into the eye of the lowest impeller.

Casing Pipe / Line Shaft Tube

Made of steel. Concentrically threaded for line shaft bronze bearings provided at intervals of 1.5m.

Column Pipe

Made of steel. Concentrically threaded as per Indian standards.

Line Shaft

Made of high carbon steel. Concentrically threaded at both ends. The line shaft in oil lubricated pumps rotates in bronze bearing fitted at 1.5 m. intervals. The line shaft in water lubricated pumps has a stainless steel sleeve which rotates in cutless rubber bearing fitted in C.I. bearing retainer (spider).

Discharge Head

Robust construction. Has an integral smooth discharge elbow. In water lubricated pumps, the discharge head houses a stuffing box and gland nut. In oil lubricated pumps, it houses a tension nipple and gland nut. Standard discharge outlet flange is drilled as per IS specification.

Pre - Lubrication

For water lubricated turbine pumps, pre-lubrication tank and pipe connections with cock available for Pre-lubrication of pump shaft, bush bearings and stuffing box before starting the pumps.

VERTICAL TURBINE PUMPS with special material of construction can be supplied against specific requirement.

VARIOUS SIZES & PERFORMANCE TABLE |

Symbol |

Outside dia of bowls in mm |

Min. dia of Tubewell

in m.m. |

Range of head In mts/stage |

Range of capacity in l.p.m. |

speed in r.p.m. |

|

|

|

|

|

|

16 A2G4 |

388 |

400 |

17 - 13 |

7600 - 11370 |

1440 |

14 A2G4 |

338 |

350 |

13 - 8 |

4800 - 7600 |

1440 |

12 A2G4 |

288 |

300 |

10 - 6 |

4000 - 6800 |

1440 |

11 A2G4 |

265 |

300 |

9 - 5 |

3000 - 5500 |

1440 |

10 A3G4 |

240 |

250 |

8 - 4 |

2000 - 4400 |

1440 |

10 A2G4 |

240 |

250 |

7 - 3 |

1500 - 3100 |

1440 |

9 A2G4 |

220 |

240 |

7 - 4 |

900 - 1800 |

1440 |

7 A1G4 |

192 |

200 |

5 - 2 |

600 - 1500 |

1440 |

6 A2G4 |

172 |

200 |

4 - 2 |

400 - 1000 |

1440 |

5 A1G2 |

142 |

150 |

11 - 6 |

500 - 1050 |

2880 |

5 A1G4 |

142 |

150 |

3 - 1.5 |

200 - 550 |

1440 |

5 A2G2 |

142 |

150 |

10 - 4 |

600 - 1500 |

2880 |

5 A2G4 |

142 |

150 |

2.5 - 1 |

350 - 700 |

1440 |

4 A2G2 |

130 |

150 |

10 - 4 |

250 - 650 |

2880 |

4 A1G2 |

130 |

150 |

6 - 1 |

100 - 500 |

2880 |

4 A15G2 |

118 |

125 |

6 - 2 |

100 - 500 |

2880 |

STANDARD MATERIAL OF CONSTRUCTION |

Pump Parts |

Material / Grade |

TOP SHAFT ADJUST NUT |

STEEL |

TOP GLAND |

BRONZE -GRLTB-2 OF IS: 318 |

ENCLOSED LINE SHAFT BEARING |

BRONZE -GRLTB-2 OF IS: 318 |

SHAFT ENCLOSING TUBE |

STEEL IS: 1239 (PART 1)1968 |

COLUMN PIPE COUPLING |

CLOSED GRAINED CAST IRON |

GUIDE SPIDER |

CLOSED GRAINED CAST IRON |

LINE SHAFT |

BRIGHT STEEL |

LINE SHAFT COUPLING |

STEEL |

COLUMN PIPE |

STEEL-IS : 1239 (PART 1)1968 ( E.R.W.) |

BOWLS |

CLOSED GRAINED CAST IRON . IS : 210 GR . FG 200 |

IMPELLERS |

BRONZE/GR : LTB-2, IS: 318,'C. I. GR - FG 200, IS : 210 |

IMPELLERS SHAFT |

12% CHROMIUM STAINLESS STEEL GR . AISI - 410 |

| SAND COLLAR / SUCTION CASE |

BRONZE/GR : LTB-2, IS: 318/C. I. GR - FG 200, IS : 210 |

LINE SHAFT BEARING SLEEVE |

12% CHROMIUM STAINLESS STEEL GR - AISI - 410 |

OPEN LINE SHAFT BEARING |

RUBBER |

In view of continuous development, we preserve the right to change the design and dimensions without notice.

|

Applications >>

Applications >>